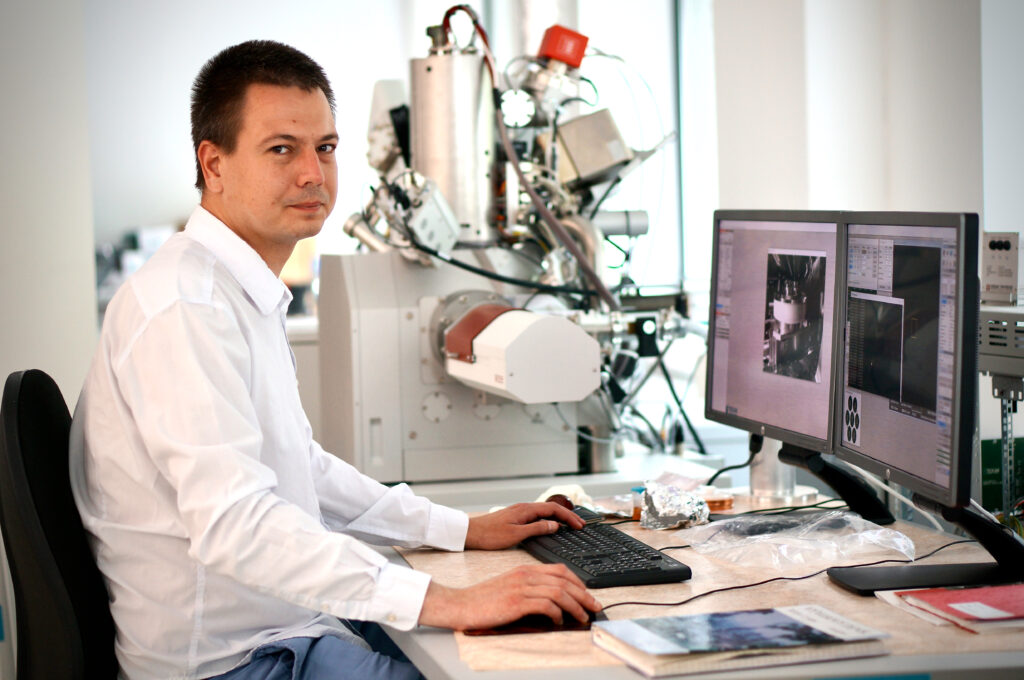

The Finalization department is the last station in the production of all TESCAN microscopes. The people here properly test and adjust each device so that installation at the customer takes place without any glitches. We asked the head Ondřej Michele what is involved in all of this.

I was intrigued that the Finalization Department is full of mostly young colleagues. What’s the average age here?

I don’t have the exact figure, but it’s true that most join us just after college. This is down to multiple reasons: firstly, it is a job suitable for graduates. Our field is so specific that we need to work with the fact that newcomers only have technical expertise and virtually no previous experience. We teach them everything ourselves. They need to understand the workings of the electron microscope and its components in great detail. This gives them a good general overview and they pick up some valuable experience. They often then proceed to other departments, such as Service or R&D. But we also have a few colleagues in their 50s who have worked here for years. It is demanding and fulfilling work and you get to see the results relatively quickly.

What is Finalization and what does it entail?

A microscope already comes to us fully assembled from the Assembly department. The chamber is tested for any leakage, and it must be able to maintain a vacuum. It also goes through a basic software test. Finalization begins in clean and super-clean production rooms, where the microscope gets its most sensitive components – the column and the manipulator. The finalizer then takes over, plugs it in and switches it on. Each piece produced will undergo precise testing to identify any shortcomings. It’s like the first test drive with a car that has just been made. The difference is that there is no mass assembly-line production, but each piece is essentially made to measure, according to the customer’s requirements and the purposes of their investigations.

What happens then?

If a deficiency is identified during testing, it will be removed and tested again. Most commonly, there are various sources of interference – hidden faults in parts or electronics that can’t be detected until the microscope is switched on. The more complex and expensive the configuration, the more difficult it is to test, but we must make sure that everything works. Once finalization is complete, the microscope is partially disassembled again, packaged and shipped. After we are done with it, the machine is switched on only at the customer site and everything must work at 100 percent.

How long does finalization take and what happens if you come across deficiencies?

It takes two weeks to finalize simpler microscopes, and usually five to six weeks for more complex dual-beams. If we find a glitch in the microscope, in the case of simple configurations, the finalizer will be able to fix it himself, but with more complex instruments, it may require replacement of a specific component and additional technological time. For example, it takes one week to dismantle and reassemble a column, and we cannot rush. Fortunately, it happens only rarely, and most complications can be cleared up quickly. Finalizers need to be able to cope.

How big is your department?

Like all of TESCAN, we are growing constantly. When I started as a finalizer ten years ago, there were about ten of us. We are currently over 30 and another five or so will join this year. We can potentially finalize up to 40 devices at a time, but most often we finalize up to twenty-five at a time. We discuss among ourselves and learn from each other. Communication is very important for us, both within the department as well as with the rest of the company.

And that is due to proper planning throughout Production, is it?

That too, but mostly we give feedback to R&D, Assembly, or the Quality department. We are the first to switch on the microscope and can discover any deficiency in the whole system that needs to be analyzed so that we can prevent it from it occurring again. If we see a defect in some component more regularly – it could just be a cable bundle – we need to initiate changes in the manufacturing or purchasing process. Fortunately, we are all in the same building, and so we can work together flexibly.

That means your work is constantly changing…

Until we switch on the microscope, we never know what we’re in for. On the other hand, the quality of the production is really high, so we are rarely surprised by anything. There’s no room for error in our department anymore, so it takes a lot of responsibility, nothing can be overlooked. So, too, each microscope will be checked by at least two finalizers. Sometimes it’s literally detective work where you see that something doesn’t quite add up, and you have to hunt down the cause.